MASTER

ECO-FRIENDLY TECHNOLOGIES INDIGO DYEING MACHINES

| beyond the limit of traditional technology Fashion requires Creativity ... Creativity requires innovation ... Innovation must be sustainable ... Bingo is the synthesis of all this! | |

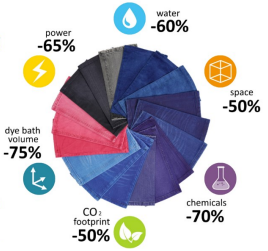

Bingo is the answers to fashion needs introducing a new class of “denims”: piece dyed with pure indigo and sulphur colors with the innovative Nitrogen technology. Bingo introduces sustainability in dyeing going beyond the traditional processes limits, reducing consumptions of chemicals, water, power and, in one word, production costs, giving designers new horizons to be explored. |

|

| |

Advantages compared with traditional dyeing technologies:

Performances thanks to its exclusive technology:

|

- We have been designing and manufacturing only dyeing machines for over fifty years

- We are the only ones to have an R&D department with a laboratory and pilot plant, for the study, research and testing of new ecological dyeing technologies.

1972:

Manufactured Europe's first indigo slasher dyeing machine.

1975:

Manufactured the first "modular" dyeing machine - INDIGO model.

1980:

Manufactured and marketed the world's first dyeing machine INDIGOLOOP model

1981:

Manufactured the "Bi-Loop" type machine (with 2 dyeing vats), evolution of the previous Loop model.

1985:

Manufactured the dyeing machine with double flow vats, INDIGOFLOW model, unsurpassed for its technology and operative flex

1991:

Patented the oxidation intensifiers "Rapidsky"

1993:

Patented the "Twinflow" vats, to dye at full capacity with indigo and at reduced capacity with other dyestuffs.

Manufactured the only machine, still running world-wide, for the dyeing of two overlapped warp chains, mod. LT/2000 (LEGLER patent), with automatic setting of the dyeing cycle fully monitor equipped - with movable creels with quick lot change system "WARP LINK" by the insertion of a piece link to eliminate the yarn wastage.

Manufactured the only machine, still running world-wide, for the dyeing of two overlapped warp chains, mod. LT/2000 (LEGLER patent), with automatic setting of the dyeing cycle fully monitor equipped - with movable creels with quick lot change system "WARP LINK" by the insertion of a piece link to eliminate the yarn wastage.

1995:

Patented "Rapidwas" vats, which enhance washing with sensible water saving.

1997:

Patented the "Ecorapidwash®" vats, further improvement of the "Rapidwash" model.

2004:

Patented "GENIUS1", dyeing integrated module, in inert environment, for colordenim.

2005:

Manufactured the indigo rope dyeing machine, INDIGOROPE, fully automatic - modernity added to tradition.

2006:

Patented "GENIUS2", indigo dyeing integrated module, in inert environment.

Patented "GENIUS3", dyeing integrated module, in inert environment, with foam dyestuffs.

Patented "GENIUS3", dyeing integrated module, in inert environment, with foam dyestuffs.

2007:

Manufactured the hydrosulphite computerized dosing and dissolving system.

2008:

Manufactured the inert environment dyeing machine, INDIGOGENIUS model, with only two vats (Genius modules) - the much evolve

2010:

Patented the "IDR" Indigo Dynamic Reduction system, for the use of indigo powder with the advantages of the indigo solution.

2015:

Patented the "Ecoturbowash" turbodynamic washing system, multiplies the washing effect halving the water consumption.

2016:

Patented the oxidation intensifiers "Deepsky"

2016:

Patented oxidation groups "Ecosky", with variable and recoverable yarn capacity, reduce significantly the yarn waste to batch change.

2016:

Patented "EUREKA" multifunctional module for indigo and sulphur dyestuffs dye, both traditionally in air and in inert environment.

2018:

Manufactured the first machine in the world, "EUREKA" model usable both in air and in inert environment.

For the discontinuous dyeing of fabrics, we have:

2018:

Patented dyeing machine, multifunctional, in inert environment, "BINGO" model.